Drywall Screws

Description of Drywall screws

Drywall screws, also known as wallboard nails, are used to install a variety of gypsum board, ceiling suspended ceilings, lightweight partitions, light steel keel, etc.. The biggest feature of the exterior is the shape of the horn head, drywall nails from carbon steel to go through a series of processes to become the final drywall nails, drywall nail process annealing, drawing, punching grooves, thread rolling, heat treatment, each process is strictly controlled, only qualified quality drywall nails will be shipped to the hands of customers.

Advantages of drywall screws

1.Self-tapping threads: wider, sharp and pointed threads, suitable for parts that do not need tapping.

2. Oxidation blackening: increase the effect of anti-oxidation and anti-corrosion plating on the surface.

3. Carbon steel material: excellent weldability, cold forming and casting.

4. Favorable price: self-tapping nail manufacturers, no middleman price difference, direct factory price

Quality Inspection

Why choose us?

1.Scale: 10+ years self-tapping nail manufacturers, strength business supply

2. Quality: layers of raw materials screening, technical personnel layer by layer to check

3. Price: self-tapping nail source factory supply, help you save 20% of the procurement costs

4. Service: self-tapping nails one-stop procurement services, the source of factory supply

Production Process

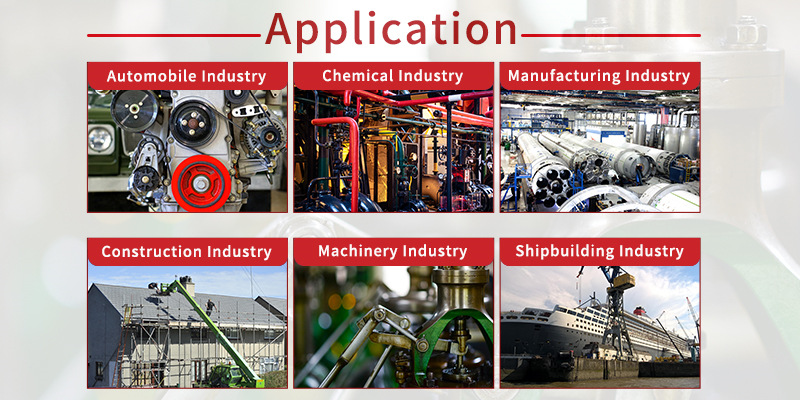

Application of Drywall screws

Black drywall screws are commonly used to install all kinds of gypsum boards, ceiling suspended ceilings, light weight partitions, light steel keel, etc. The threads of drywall screws are very special and will hold the connected objects tightly, so the drywall screws are widely used.

Application Diagram

Our Certification

FAQ

1. Drywall screws selection criteria.

A. head to round, because of the production process, many manufacturers produce drywall nails head may not be very round, some are even slightly square. The problem is that after screwing in can not be completely matched with the gypsum board.

B. The tip should be pointed, especially when you are used in the light steel keel. Drywall nails generally require a sharp angle between 22 to 26 degrees, requiring the head of the sharp corner full, can not have dragging wire, cracking phenomenon. The "tip" is important for drywall nails, because the use of drywall nails do not play prefabricated holes, directly screwed, so the tip also bears the function of drilling through. Especially when used in the light steel keel, bad tip will lead to drilling, directly affecting the use.

C. Can not be eccentric. A simple way to determine if the drywall nail is eccentric is to place the round head down on the table and see if the threaded part is vertical and should reside in the middle of the head. If the screw is eccentric, the problem is that the power tool will shake when screwed into the short point screws, okay, if the longer screws encounter this situation is a big problem.

Our company can meet all of the above criteria, if you are interested, please contact us, we will send you a complete bolt catalog and a free discount drywall nail price.

2. Do you offer any discounts on the price of your drywall screws?

Usually, all bolt manufacturers adopt two different sales models, one is to win by price and the other is to win by quality.

Our company's aim is to do our best to reduce the customer's input while maintaining the quality of the bolts.

We can guarantee that our prices are reasonable among all manufacturers who can provide bolts of the same quality.

According to the feedback from our customers, our bolt prices are value for money and we look forward to cooperating with you.